BIM

Wikipedia states that the definition of BIM or Building Information Modeling is a process involving the generation and management of digital representations of physical and functional characteristics of places. Or in simpler terms, representing a building and its many characteristics in a cohesive 3D Virtual Model. This type of modeling is quickly changing the face of Engineering today. With this fast expansion there is a major component that sometimes gets lost in translation of this revolutionary topic, and that is the people behind the models. Autodesk previously discussed the importance of "People" in BIM management and declared that BIM provides an opportunity to teach staff regardless of age, gender, or experience about this process in hopes that the effective transformation of knowledge in the workplace will be one of great success for the future. The article points out that many firms who choose to adopt BIM as a company wide process of modeling are stuck focusing on the mechanics of adoption (tools, standards, processes, training) instead of looking at the work methods and mindsets of those using the programs. It claims that this transformation will be more effective if the people of the firm can harness both the mechanics and the culture of the programming process.

After reading this article, and having a year of experience in a highly competitive engineering firm that is slowly adopting company wide BIM processes, I agree with what this article is trying to point out. When working in a firm that has a wide distribution of ages and experience levels it is hard to get everyone to adopt the BIM requirements right away. The company I was in focused mainly on the mechanics of the programming instead of addressing the culture aspect of BIM also. This made it hard to use BIM programs for specific project due to employees being unable to manipulate and comprehend the programs used to represent the projects. I think that if more seminars had been held at the company for Revit and BIM programs, more projects would be done in that manner. In my opinion BIM is the process of the future and as more and more people graduate college with knowledge in BIM programming, the possibilities for design are limitless.

For my explanation of BIM, I focused heavily on how BIM directly effects those who use it and what standpoint is most effective for this type of system to be adopted as a company wide process. After reading my a post from my group mate Mikaela Price, I became aware of another aspect of BIM that I wasn't aware was something being used in society today. She talked about how BIM utilized "smart" building technology in a way that it allows store owners to know the movements and position of their shoppers by the wifi signals emitted from their smartphones. I like that she focused on a specific example of BIM technology versus looking at it as a broad spectrum topic.

3D-PRINTING

The realm of 3D printing is one that has had many breakthroughs since it was introduced into the science world. Originally printing plastic products only, advancements in technology have allowed for the ventures of printing with more advanced materials than plastic for various uses. After reading "The Internet of Anything: The 3-D Printer That Can Spit Out Custom Electronics", it proves that 3D printing has gone above just plastic. The Voxel8 printer, as designed by Jennifer Lewis, is one that allows for the printing of custom electronics. She designed this printer in hopes that the market for printing electronic wearables, like hearing aides, could take off and be utilized for the advancement of human health. The argument identified is that the industry for 3D printing has severely limited itself by only printing with plastic.

In my opinion, I completely agree with Lewis' statement. While I find it amazing what can be 3D printed with plastic these days, the idea of printing electronic wearables, prosthetic limbs, synthetic organs, and even building materials are ones that should be seriously considered. Previously a Harvard student created a printer with the ability to print colored makeup from taking the RGB characteristics of a pixel on an image. That right there shows that anything is possible in the realm of printing and 3D printing of materials and objects. It would be foolish to not push the envelope of 3D printing to more advanced technologies and materials, because the results are endless. They could have a huge impact on how we live our lives every day.

For my explanation of 3D Printing, I focused on looking into a specific printer used for this unique process and the capabilities of that one specific printer. My classmate Grigorios Papadourakis looked a similar aspect of 3D printing that I felt was noteworthy of incorporating into my own post. He explored a company called Nervous System which is a group that looks into 3D printing by examining how what they print is able to move once constructed, and how their products can be modified and enhanced after printing. I agree with how he tied this company's ideas into how this could be mirrored for future structural use. There is a distinct possibility of some sort of 3D Printing being used for material requisition on a job site someday, which is why I feel its important to pay attention to the technological advancements in this area.

STRUCTURES

As technology advances more and more each year so do the structures we see being built all around us. While there are plenty of interesting architectural structures being built in the US to see more advances structures it is key to look outside of the US. Many examples of interesting structures can be found all over the world using advanced types of building technology. For example, the Landesgartenschau Exhibition Hall found in Germany is a timber structure gallery space that was robotically fabricated. With its advanced shape and interlocking pieces, the exhibition hall is a great example of an innovative structure. Structures built with this type of technology are becoming more and more prevalent each year due to advancement in technology and those willing to push the normal envelope of design.

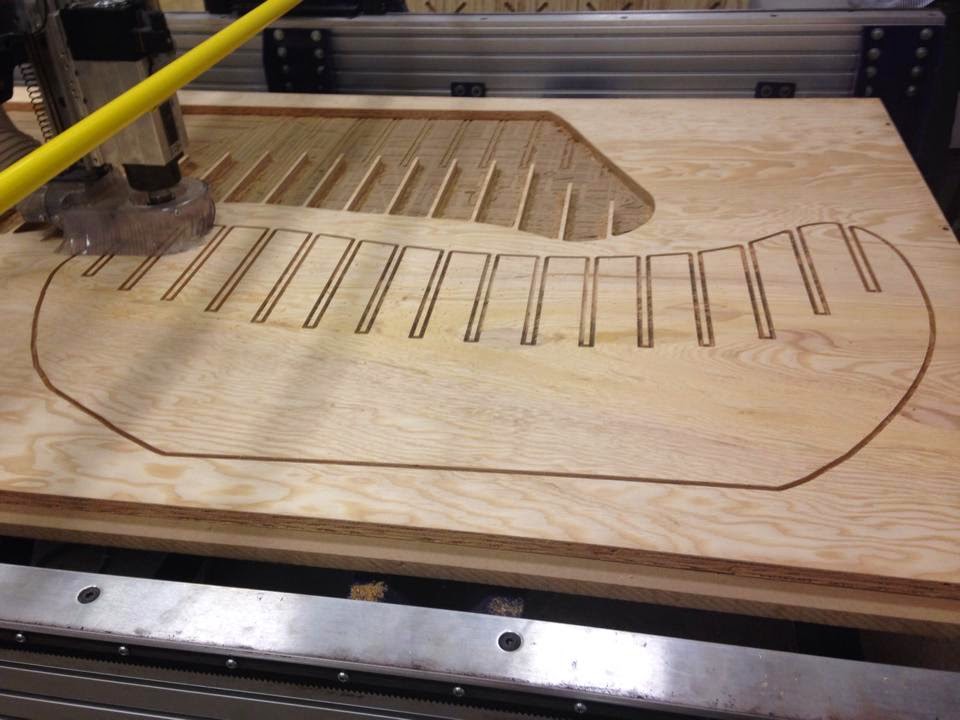

I believe this is a great way to design and build structures because it shows the capabilities of engineers and designers and gives a glimpse of what we will be capable of in the future. To see a structure like this come together is extremely satisfying, and after working on my own design project to digitally create a virtual 3D model of a waffled park bench structure, and then using robotic fabrication to physically make the bench, I can truly appreciate the meaning behind this type of structural design.

Above are images of the project I was a part of to design this bus stop bench located on 37th and Brown.

To add to my own discussion, after reading Drew Sivertsen's section on Structure I realized that there a lot of components that go into the building technology of a building's design. And I agree with his statement that building technology is a major driving force behind innovative designs of structures in today's society. While a lot of these technologies are seen outside of the US, more and more could and should be used to build structures in the US because it would add to our diversity as a nation as well as provide learning opportunities for engineers all over the country.

FUTURE

After evaluating and commenting on the three topics as mentioned above, BIM, 3D Printing, and Structures, it is clear that ideas pertaining to these topics will constantly be advanced as times goes on. This leaves so many opportunities in engineering to be discovered. If these topics can be integrated together in an effective way the design ideas of the future will be endless and I look forward to seeing them in the future as well as have the opportunity to be a part of some future projects.

REFERENCES

"Building Information Modeling." Wikipedia. Wikimedia Foundation, 2 Jan. 2015. Web. 08 Jan. 2015. <http://en.wikipedia.org/wiki/Building_information_modeling>.

Finley, Klint. "The Internet of Anything: The 3-D Printer That Can Spit Out Custom Electronics | WIRED." Wired.com. Conde Nast Digital, 05 Jan. 2015. Web. 09 Jan. 2015. <http://www.wired.com/2015/01/internet-anything-3-d-printer-can-spit-quadcopter-parts/>.

Frederickson, Trent. "Robotically Fabricated Landesgartenschau Exhibition Hall in Germany - Designboom | Architecture & Design Magazine." Designboom Architecture Design Magazine Robotically Fabricated Landesgartenschau Exhibition Hall in Germany Comments. DesignBoom, 24 June 2014. Web. 11 Jan. 2015. <http://www.designboom.com/architecture/robotically-fabricated-landesgartenschau-exhibition-hall-06-25-2014/>.

Speden, Liam. "The "People" Part of BIM Adoption." 'BusinessofBIM' Autodesk, 18 Dec. 2013. Web. 11 Jan. 2015. <http://autodesk.typepad.com/businessofbim/2013/12/the-people-part-of-bim-adoption.html>.

http://ae-510-ay14-15.blogspot.com/2015/01/b1-group-b-price.html

http://ae-510-ay14-15.blogspot.com/2015/01/b1-group-b-grigorios-papadourakis.html

http://ae-510-ay14-15.blogspot.com/2015/01/b1-group-b-sivertsen.html

http://ae-510-ay14-15.blogspot.com/2015/01/b1-group-b-price.html

http://ae-510-ay14-15.blogspot.com/2015/01/b1-group-b-grigorios-papadourakis.html

http://ae-510-ay14-15.blogspot.com/2015/01/b1-group-b-sivertsen.html

As your blog clearly states,it its truly amazing to imagine the possibility of being able to print using many materials and even being able to use a printer to create organs and limbs! It's also most certainly not foolish to think that one day every household will one day possess a printer in the their home! There will surely be some sort of Amazon or Walmart that we could purchase blueprints from a click of a button.

ReplyDeleteI liked the way you described BIM as being very important to experience for all graduate students. I agree with you that having more knowledge in BIM would leads to have more intelligent project.

ReplyDeleteAlso, Lewis' 3D printer opens wide door to 3D printing field. Not only in small basic plastic tools, but in more advanced applications especially medical aids.